About CNC CMM

CNC CMM

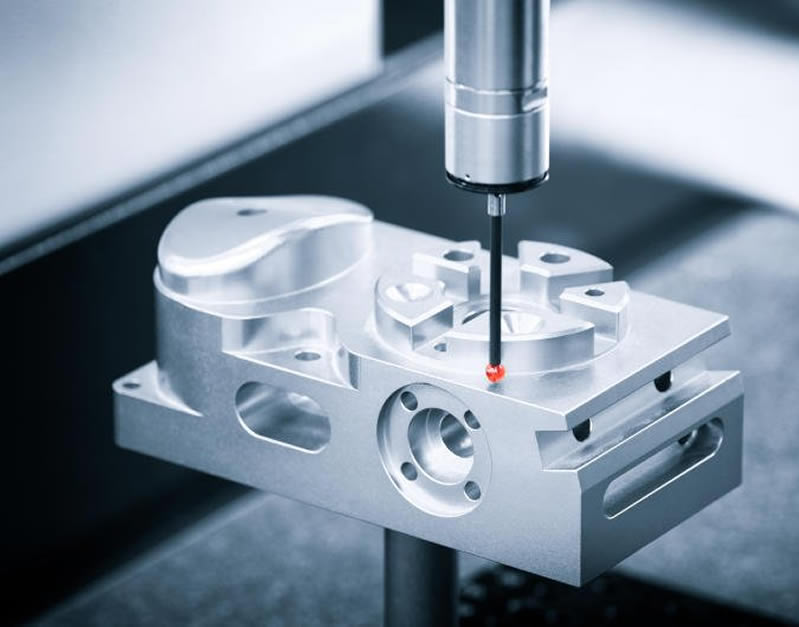

A coordinate measuring machine (CMM) is a device that measures the geometry of physical objects by sensing discrete points on the object’s surface with a probe. Various probes are used in CMMs, including mechanical, optical, laser, and white light. Depending on the machine, the probe position may be manually controlled by an operator or computer. CMMs typically specify a probe’s displacement from a reference position in a three-dimensional Cartesian coordinate system (i.e., with XYZ axes). In addition to moving the probe along the X, Y, and Z axes, many machines also allow the probe angle to be controlled to allow measurement of surfaces that would otherwise be unreachable.

At BT, we use CMM daily to ensure all our products meet specifications. We would be happy to give you a tour of our facility. Contact us for more information or a quote on your next project.

Contact Us

Call

(408) 609-1305

bang@bthighprecisionmachining.com

Address

11135 N. 7th Street Unit B

San Jose, CA 95112